HSR-SR3400 Industrial Robot

“The HSR-SR3400 series robots are small in size, light in weight, high in precision, and have a variety of load positions for more flexible movement.

1. Cost-effective

Low cost, What you buy is a general industrial robot, which can be reprogrammed for other handling, assembly operations,.The costs can be recovered in one year.

2. Long service life

Using high-precision and high-rigidity harmonic reducer which can use last for several decades. Once you buy, benefit for decades.

3. High speed performance

Using low-speed ratio high-precision reducer with ultra-fast cycle time and the fastest cycle time up to 0.35S

4. High integration

The built-in signal line and the air pipe of the main body are plug and play, no complicated wiring is required, and the internal cable has no slip, and the fault-free rate can be maintained for a long time.

5. High precision

Except the use of high-precision harmonic reducer, the imported high-precision ball screw ball spline is also used, and the end repeat positioning accuracy is reaching ±0.01MM.

6. High smoothness

The advanced control system and servo drive system are used to achieve high-speed and smooth motion performance, and the transition point is almost zero-time pause.

7. High rigidity

Its linear movement axis at the end gives it a good stiffness in the Z direction, which is especially suitable for assembly work.

8. Load position practicality

According to the actual end load, the customer can adjust the load position and simple operation to improve the robot’s running tempo. “

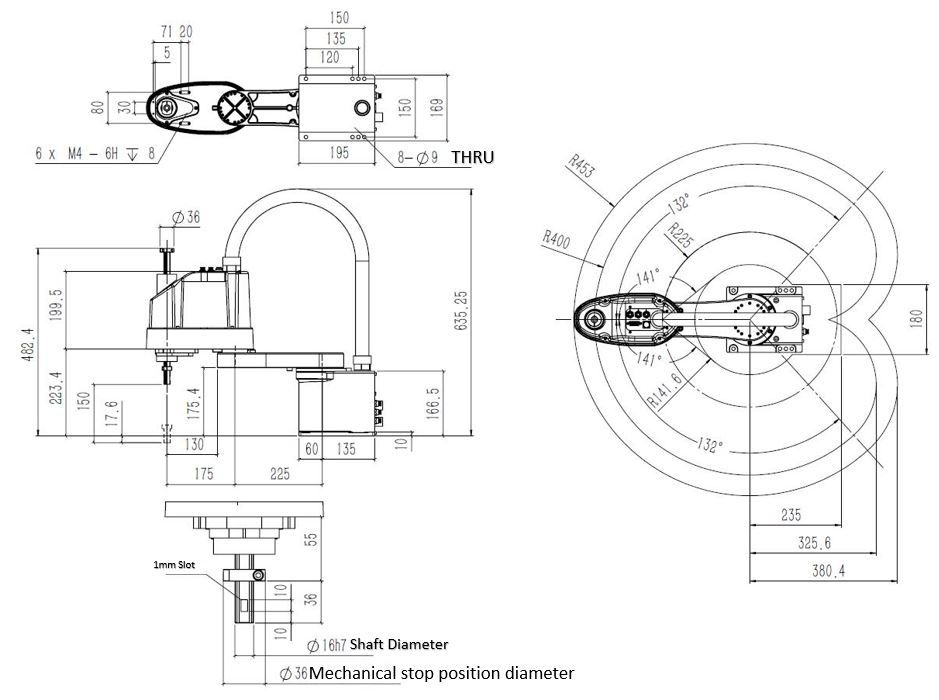

| Industrial robot | HSR-SR3400 | |

| Degree of freedom | 4 | |

| Maximum load/specified load | 3kg/1kg | |

| Maximum working radius | 400mm | |

| Repeatability | ±0.01mm | |

| Range of motion | J1 | ±132° |

| J2 | ±141° | |

| J3 | 0-150mm | |

| J4 | ±360° | |

| Rated speed | J1 | 360°/s,6.28rad/s |

| J2 | 470°/s,8.19rad/s | |

| J3 | 710mm/s | |

| J4 | 1500°/s,26.16rad/s | |

| Maximum speed | J1 | 530°/s,9.24rad/s |

| J2 | 700°/s,12.21rad/s | |

| J3 | 1065mm/s | |

| J4 | 2600°/s,43.35rad/s | |

| Allowable moment of inertia | J4 | 0.05kg㎡/0.005kg㎡ |

| Allowable torque | J4 | 3.29Nm |

| Applicable environment | temperature | 0~45° |

| humidity | 20%~80% | |

| other | Avoid contact with flammable, explosive or corrosive gases and liquids. Keep away from electronic noise sources (plasma). | |

| Cable Length of Instructor | Optional (if configured, the teach pendant cable length is 8 meters) | |

| Body-cabinet connection length | 3metre | |

| I/Oparameter | Digital:32 inputs, 31 outputs (one for control cabinet fault indicator output) | |

| battery capacity | 0.6kVA | |

| rated power | 0.5kW | |

| Rated voltage | Single phaseAC220V | |

| Rated current | 2.7A | |

| protection grade | IP54 | |

| Installation method | Ground installation、desktop installation | |

| Body weight | 17kg | |

| Control cabinet protection grade | IP53 | |

| Control cabinet size | 500(wide)×270(thick)×530(high)-can stand | |

| Control cabinet weight | 38KG | |

Series

Model

Download

PLC

PLC

PLC

HCA1P&A2P user manual-V1.1-.pdf

HC-A1&HC-A2 Programming Manual

TX-USB-AW Driver