HSR-JR612 Industrial Robot

HSR-JR612 is a high-performance general-purpose small-load joint robot. It relies on the technology of accumulation on the servo control technology of Huazhong CNC. It uses self-developed control technology and high-performance servo motor to sense the long arm span and large load in the same level of robot. It adopts high rigidity arm, advanced servo, fast-moving speed, repeat positioning accuracy of up to ±0.06mm, and motion radius of 1555mm, which is suitable for grinding, handling and welding industries.

1. Accurate machining process control and strict assembly control.

2. Strict precision control. Trajectory accuracy test by Foreign advanced measurement and calibration equipment.

3. Imported high-precision reducer, matching high-performance servo motor to ensure smooth start and stop of the robot.

4. High-performance control system that allows robots to run quickly and accurately.

5. Load up to 12Kg.

6. Arm span up to 1555mm.

7. Factory stability test for up to 7*24 hours to ensure stable quality.

8. Rich user interfaces, the internal wiring of the main body integrates the servo motor power line and coding line, as well as the user-friendly DB15 interface and the φ8 air pipe interface, which not only maintains the overall appearance, but also facilitates the fixture wiring application.

9. The 4-axis screw has a hollow design, and the user’s air tube can pass through the arm to reduce the exposed air tube.

10:Standard and high degree of protection model for the electronics industry.

11:Excellent servo controller application platform, strict quality control of core components, and technical support for customer satisfaction.

12:Maintain good cooperative relations with domestic quality suppliers and provide relevant supporting visual and application products for customers.

| Industrial robot | HSR-JR612 | |

| Degree of freedom | 6 | |

| specified load | 12Kg | |

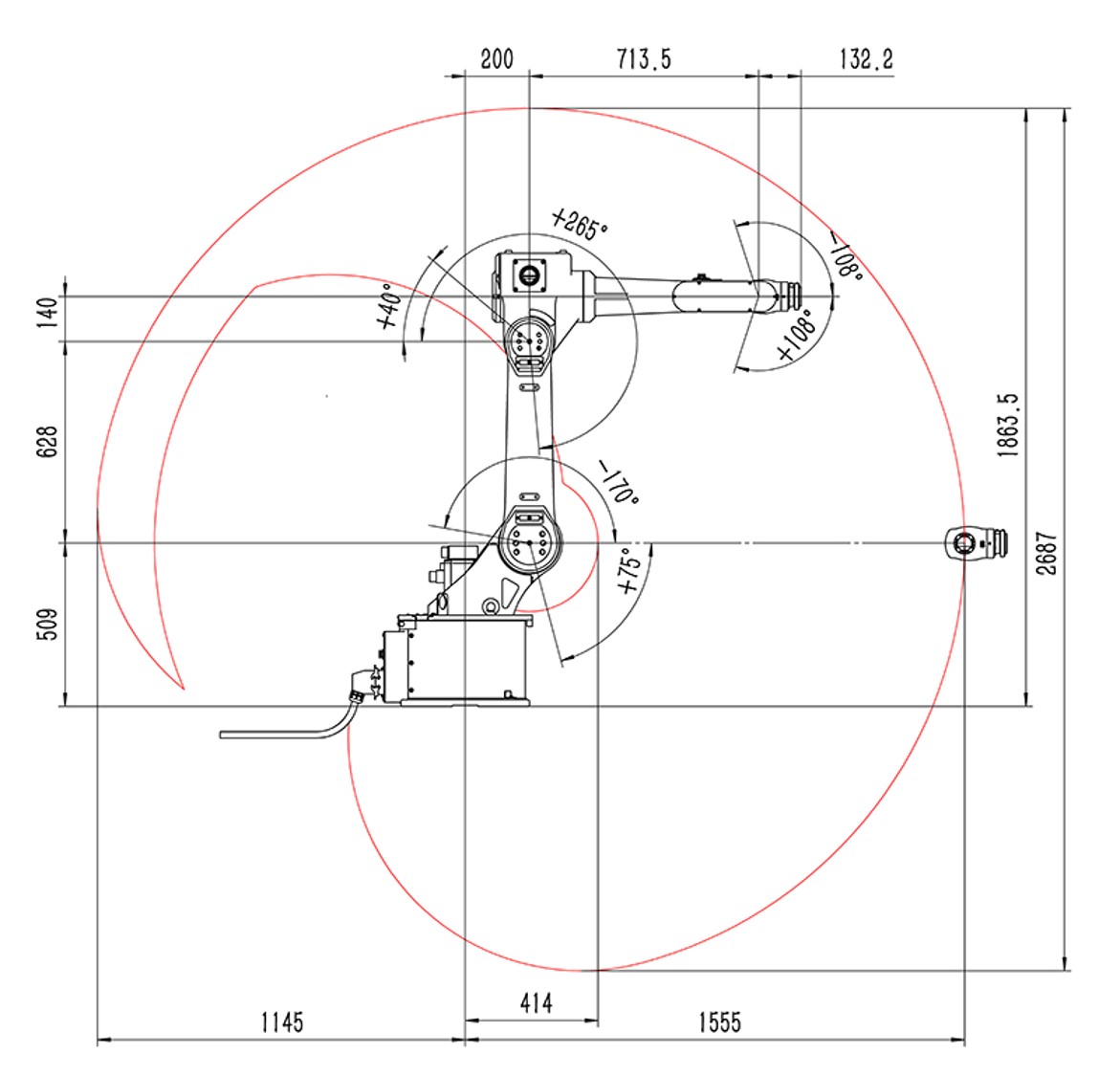

| Maximum working radius | 1555mm | |

| Repeatability | ±0.06mm | |

| Range of motion | J1 | ±168° |

| J2 | -170°/+75° | |

| J3 | +40°/ +265° | |

| J4 | ±180° | |

| J5 | ±108° | |

| J6 | ±360° | |

| Rated speed | J1 | 148°/s,2.58rad/s |

| J2 | 148°/s,2.58rad/s | |

| J3 | 148°/s,2.58rad/s | |

| J4 | 360°/s,6.28rad/s | |

| J5 | 225°/s,3.93rad/s | |

| J6 | 360°/s,6.28rad/s | |

| Maximum speed | J1 | 197.33°/s,3.44rad/s |

| J2 | 197.33°/s,3.44rad/s | |

| J3 | 197.33°/s,3.44rad/s | |

| J4 | 600°/s,10.47rad/s | |

| J5 | 375°/s,6.54rad/s | |

| J6 | 600°/s,10.47rad/s | |

| Allowable moment of inertia | J6 | 0.17kg㎡ |

| J5 | 1.2kg㎡ | |

| J4 | 1.2kg㎡ | |

| Allowable torque | J6 | 15Nm |

| J5 | 35Nm | |

| J4 | 35Nm | |

| Applicable environment | temperature | 0~45° |

| humidity | 20%~80% | |

| other | Avoid contact with flammable, explosive or corrosive gases and liquids. Keep away from electronic noise sources (plasma). | |

| Cable Length of Instructor | 8metre | |

| Body-cabinet connection length | 6metre | |

| I/Oparameter | Digital:32 inputs, 31 outputs (one for control cabinet fault indicator output) | |

| battery capacity | 3.8kVA | |

| rated power | 3kW | |

| Rated voltage | Three phaseAC380V | |

| Rated current | 5.4A | |

| Body protection grade | IP54/IP65(wrist) | |

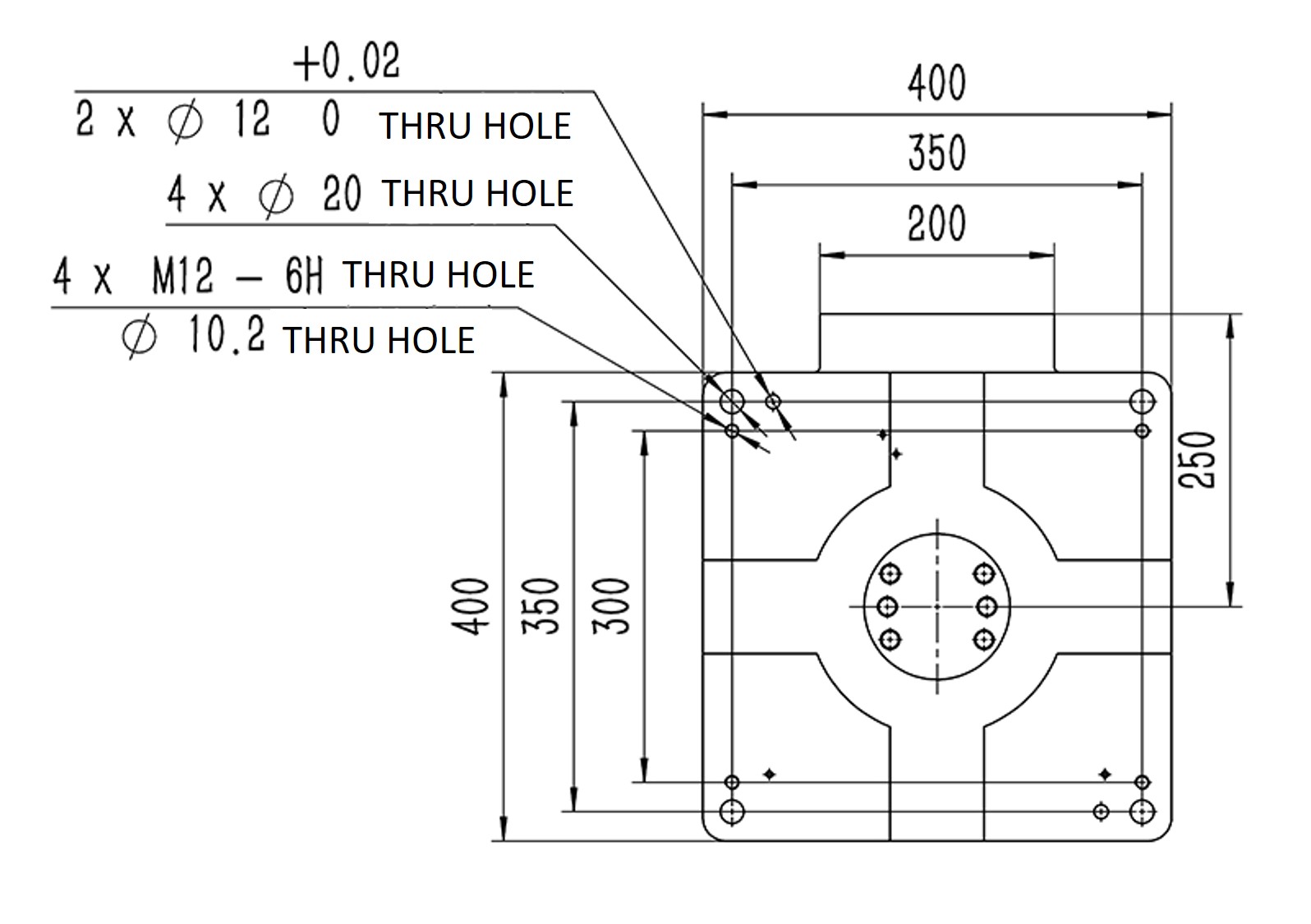

| Installation method | Ground installation、side mount installation | |

| Body weight | 196kg | |

| Control cabinet protection grade | IP53 | |

| Control cabinet size | 650mm(wide)×580mm(thick)×940mm(high)-立式 | |

| Control cabinet weight | 130KG | |

Product Outline and Mounting Dimension:

Series

Model

Download

PLC

PLC

PLC

HCA1P&A2P user manual-V1.1-.pdf

HC-A1&HC-A2 Programming Manual

TX-USB-AW Driver