HSR-HC420 Industrial Robot

The robot is mainly aimed at large stamping industry, especially automobile industry and household appliances industry. At present, the multi-joint industrial robots for large-scale stamping are mostly six-axis tandem (six-joint) robots in the market, and the price is relatively high. This kind of robot is specially designed for this situation, with relatively low production cost and absolute advantage in price. Overseas heavy-duty robots are widely used in large-scale stamping industry. Compared with domestic ones, the technology field of heavy-duty robots is almost blank. In order to respond to the market demand for flexibility, modular structure design is adopted for this robot. The arm length of the robot is designed in a variable way, and the required arm length can be determined at will for different situations. Through its strong interchangeability, the robot can derive a number of products.

1:Extra-long arm extension

The machine has a super-long arm span up to 2000 mm. It can cope with various working conditions in the stamping field and perfectly adapt to various tonnage presses.

2:Overload

The payload capacity of the machine is up to 20 kg, and the sheet area can reach 1800 mm*1000 mm. It basically covers all kinds of products in stamping field.

3:Ultra High Precision

The robot has super high precision, the accuracy reaches 0.08mm, fully meet the use of stamping industry.

4:Fast Modification

The machine adopts modular design and interchangeability. For the replacement design of the robot arm, the arm length can be customized and replaced according to the actual working conditions. Load capacity can be flexibly increased according to arm length.

5:Having innate advantages

Its 20kg load and 2000mm arm length can completely replace the 50kg six-axis robot in the stamping and handling industry, and it has the advantage of high speed. It achieves low input and high output in the automatic production process.

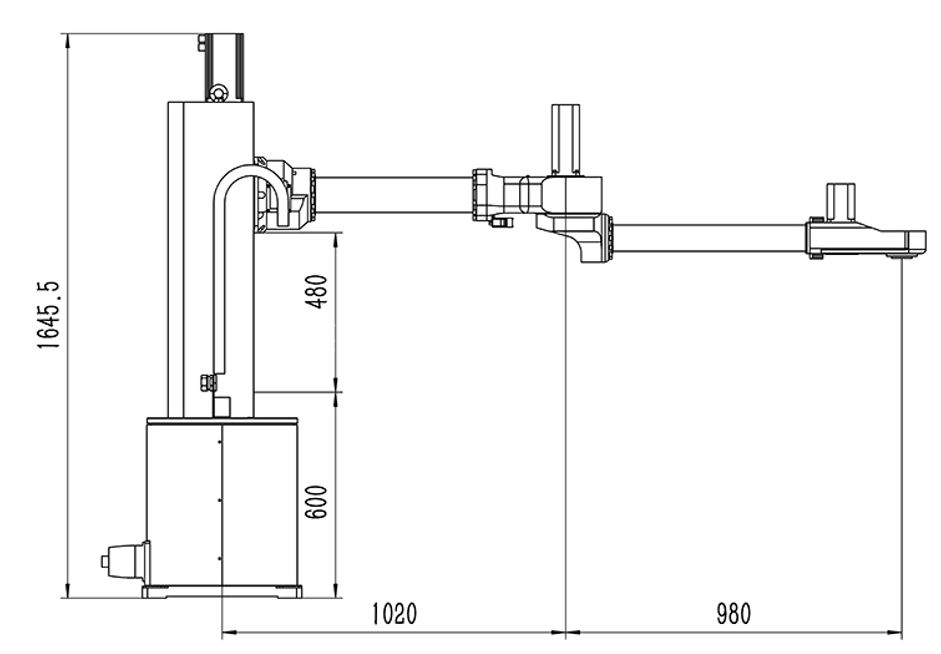

| Industrial robot | HSR-HC420 | |

| Freedom | 4 | |

| Rated load | 20Kg | |

| Maximum operating radius | 2000mm | |

| Repeated positioning accuracy | ±0.08mm | |

| Range of motion | J1 | ±145° |

| J2 | ±135° | |

| J3 | ±240mm | |

| J4 | ±180° | |

| Rated speed | J1 | 108°/s,1.88rad/s |

| J2 | 148.76°/s,2.60rad/s | |

| J3 | 500mm/s | |

| J4 | 225°/s,3.93rad/s | |

| Top speed | J1 | 216°/s,3.77rad/s |

| J2 | 198°/s,3.54rad/s | |

| J3 | 667mm/s | |

| J4 | 375°/s,6.54rad/s | |

| Admissible moment of inertia | J4 | 6.5kg㎡ |

| Allowable Torque | J4 | 90Nm |

| Applicable environment | temperature | 0~45° |

| humidity | 20%~80% | |

| Other | Avoid contact with flammable, explosive or corrosive gases and liquids. Keep away from electronic noise sources (plasma). | |

| Cable Length of Instructor | 8metre | |

| Body-cabinet connection length | 6metre | |

| I/O parameters | Digital: 32 inputs, 31 outputs (one for control cabinet fault indicator output) | |

| battery capacity | 5.6kVA | |

| rated power | 4.5kW | |

| Rated voltage | Three phaseAC380V | |

| Rated current | 8.1A | |

| protection grade | IP54 | |

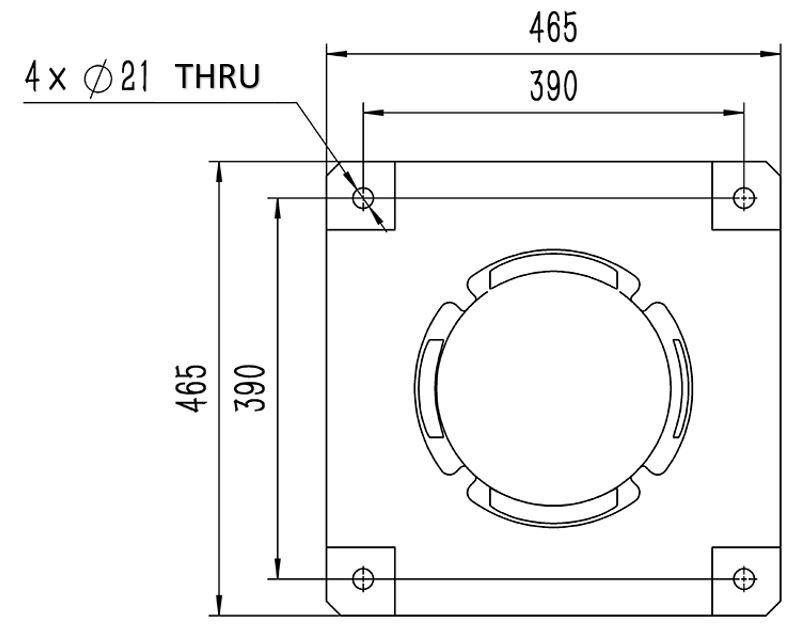

| Installation method | Ground installation | |

| Body weight | 280kg | |

| Control cabinet protection grade | IP53 | |

| Control cabinet size | 660(wide)×450(thick)×950(high)-vertical | |

| Control cabinet weight | 50Kg | |

Series

Model

Download

PLC

PLC

PLC

HCA1P&A2P user manual-V1.1-.pdf

HC-A1&HC-A2 Programming Manual

TX-USB-AW Driver