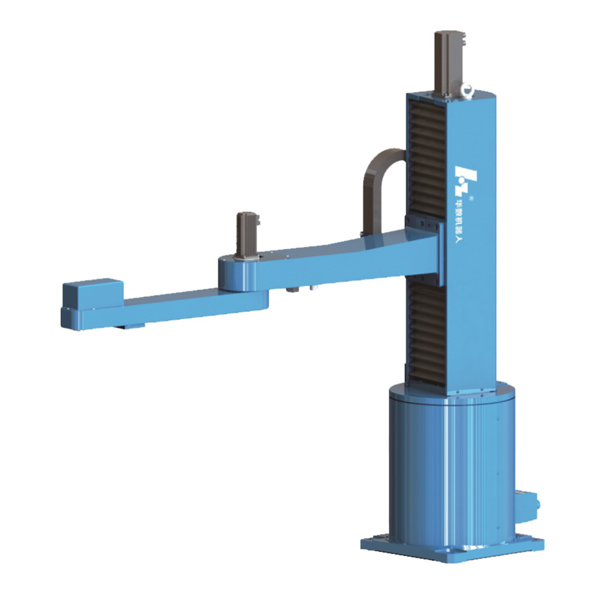

HSR-HC410A Industrial Robot

“Using unconventional R&D control system, high reliability, high stability, short motion response time, sensitive response; fast speed, high repeatability, and high-cost performance, fully meet the high demands of stamping, handling, and other industries; configure a new version of the teaching device, The operation is simple and convenient.

1. Cost-effective:

Low cost, what you buy is a general industrial robot, which can be reprogrammed for other handling, assembly operations, and also can recover costs in one year

2. Long service life:

Adopt high-precision and high-stiffness imported reducer, the machine can be used for several decades. Once you buy, will be benefit for many years.

3.High speed performance:

Using a low-speed ratio high-precision reducer, the running speed is twice that of the same-level six-joint robot

4.High precision

Using the high-precision RV reducer with the repeatable positioning accuracy of the end reaching ±0.05MM

5. High integration

The built-in signal line interface and air pipe connector of the main body use almost no external wiring during use, which greatly reduces the probability of pipeline damage and can be applied to a more severe production environment.

6. High rigidity

High-strength cast iron and cast aluminum for the key structural parts ensure high rigidity of the robot at high speeds

7. High smoothness

The advanced control system and servo drive system are used to achieve high-speed and smooth motion performance, and the transition point is almost zero-time pause.

8. High load

The maximum load of the wrist is 10kg, which can cover large workpieces and easily respond to new business orders from customers."

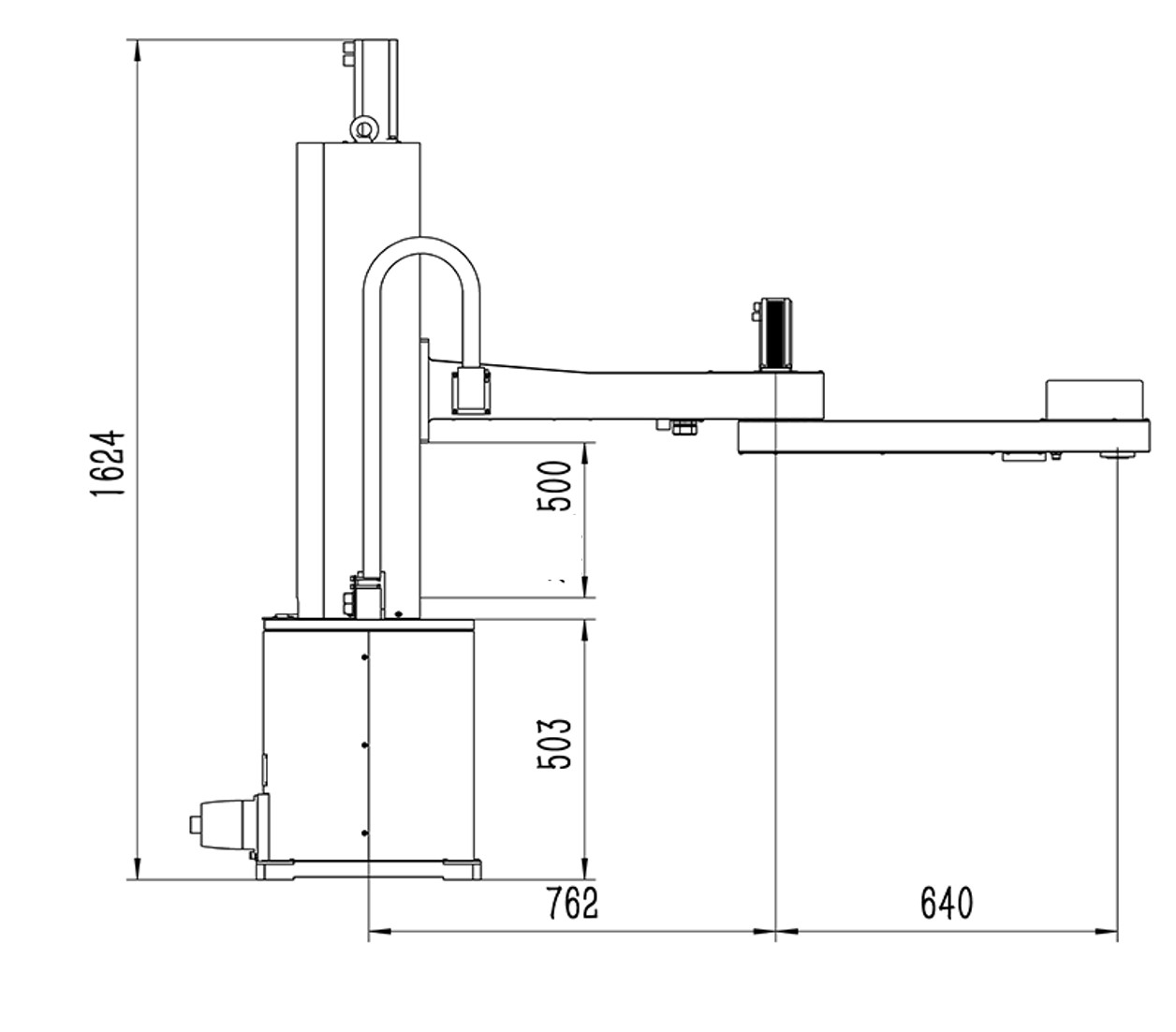

| Industrial robot | HSR-HC410A | |

| Degree of freedom | 4 | |

| specified load | 10Kg | |

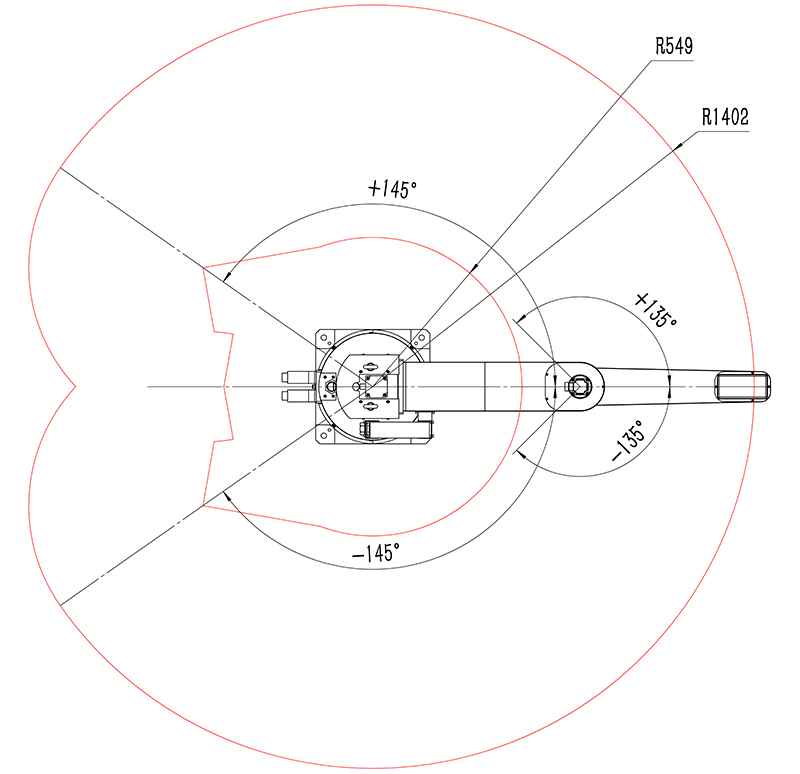

| Maximum working radius | 1402mm | |

| Repeatability | ±0.05mm | |

| Range of motion | J1 | ±145° |

| J2 | ±135° | |

| J3 | ±250mm | |

| J4 | ±180° | |

| Rated speed | J1 | 225°/s,3.93rad/s |

| J2 | 225°/s,3.93rad/s | |

| J3 | 500mm/s | |

| J4 | 180°/s,3.14rad/s | |

| Maximum speed | J1 | 300°/s,5.23rad/s |

| J2 | 375°/s,6.54rad/s | |

| J3 | 830mm/s | |

| J4 | 360°/s,6.28rad/s | |

| Allowable moment of inertia | J4 | 2kg㎡ |

| Allowable torque | J4 | 40N·m |

| Applicable environment | temperature | 0~45° |

| humidity | 20%~80% | |

| other | Avoid contact with flammable, explosive or corrosive gases and liquids. Keep away from electronic noise sources (plasma). | |

| Cable Length of Instructor | 8metre | |

| Body-cabinet connection length | 6metre | |

| I/Oparameter | Digital:32 inputs, 31 outputs (one for control cabinet fault indicator output) | |

| battery capacity | 2.3kVA | |

| rated power | 1.8kW | |

| Rated voltage | Three phaseAC380V | |

| Rated current | 3.2A | |

| protection grade | IP54 | |

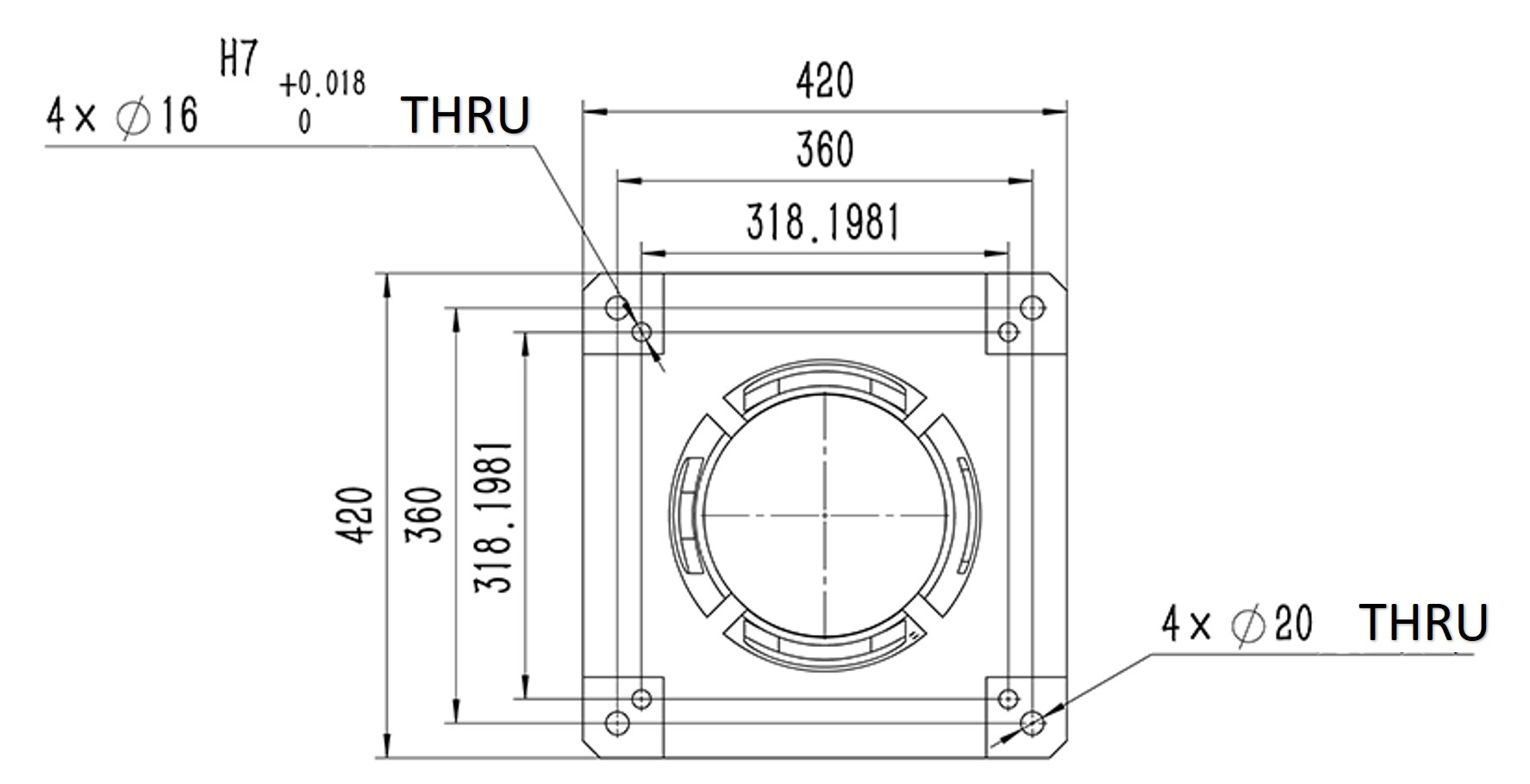

| Installation method | Ground installation | |

| Body weight | 230kg | |

| Control cabinet protection grade | IP53 | |

| Control cabinet size | 660(wide)×450(thick)×950(high)-vertical | |

| Control cabinet weight | 50Kg | |

Series

Model

Download

PLC

PLC

PLC

HCA1P&A2P user manual-V1.1-.pdf

HC-A1&HC-A2 Programming Manual

TX-USB-AW Driver